OUR FACILITY

Our facility in Kerobokan-Bali has been shaped by more than thirty years of experience assembling stretch-performance garments. Everything takes place under one roof, giving our teams a clear, predictable workflow and helping brands understand exactly how their garments move from fabric delivery to final packing.

The building follows the same practical flow every collection takes — cut → sew → QC → pack. This simple structure is one of the main reasons we are able to maintain steady timelines and consistent results for both new labels and established companies.

Cutting

Production begins in the cutting room, where recycled nylon and performance fabrics are prepared for assembly. Our cutting technicians specialise in stretch materials, ensuring each panel is clean, accurate and ready for stitching. Care at this stage sets the foundation for fit, comfort and overall garment quality.

Assembly

Swimwear and activewear are assembled by dedicated teams experienced in stretch-performance garments. Senior technicians oversee each team, guiding the process and maintaining machine standards so every piece follows the intended fit and structure. The pace is organised and consistent, allowing our teams to focus on accuracy rather than speed.

Getting Started

One of the first questions brands have is how to get started. We keep the handover process clear and simple, whether you’re working with plain colours, digital prints, or a mix of both.

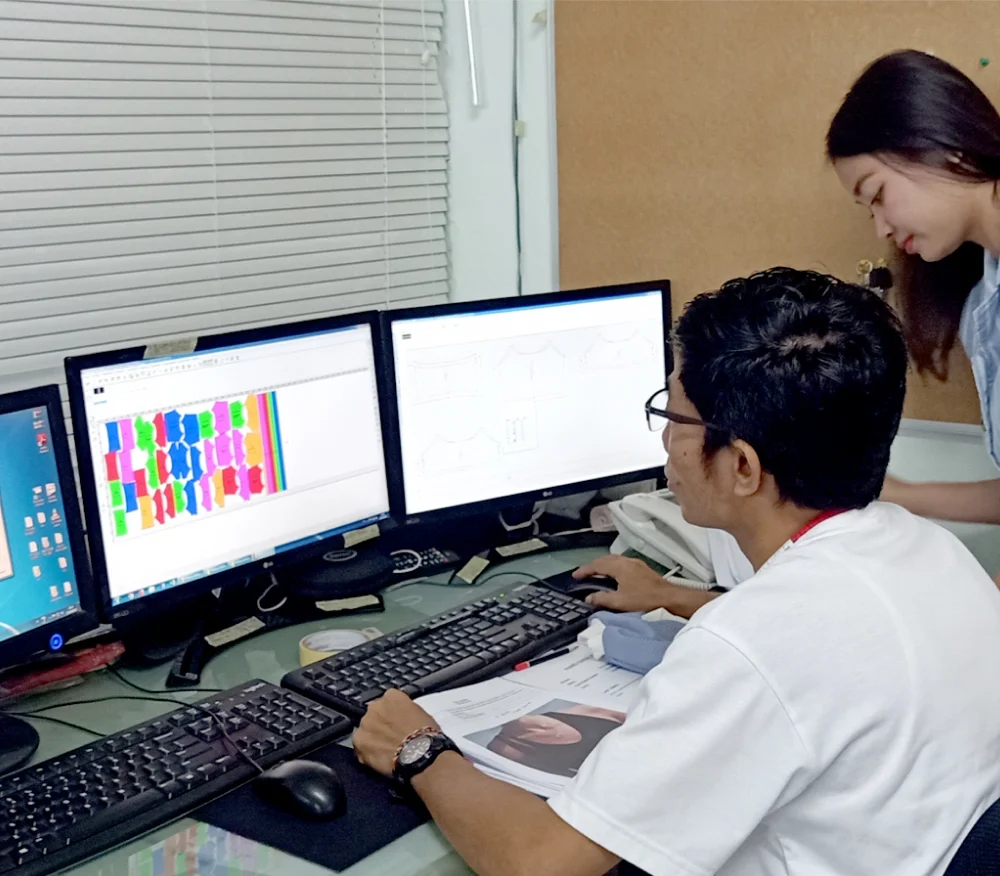

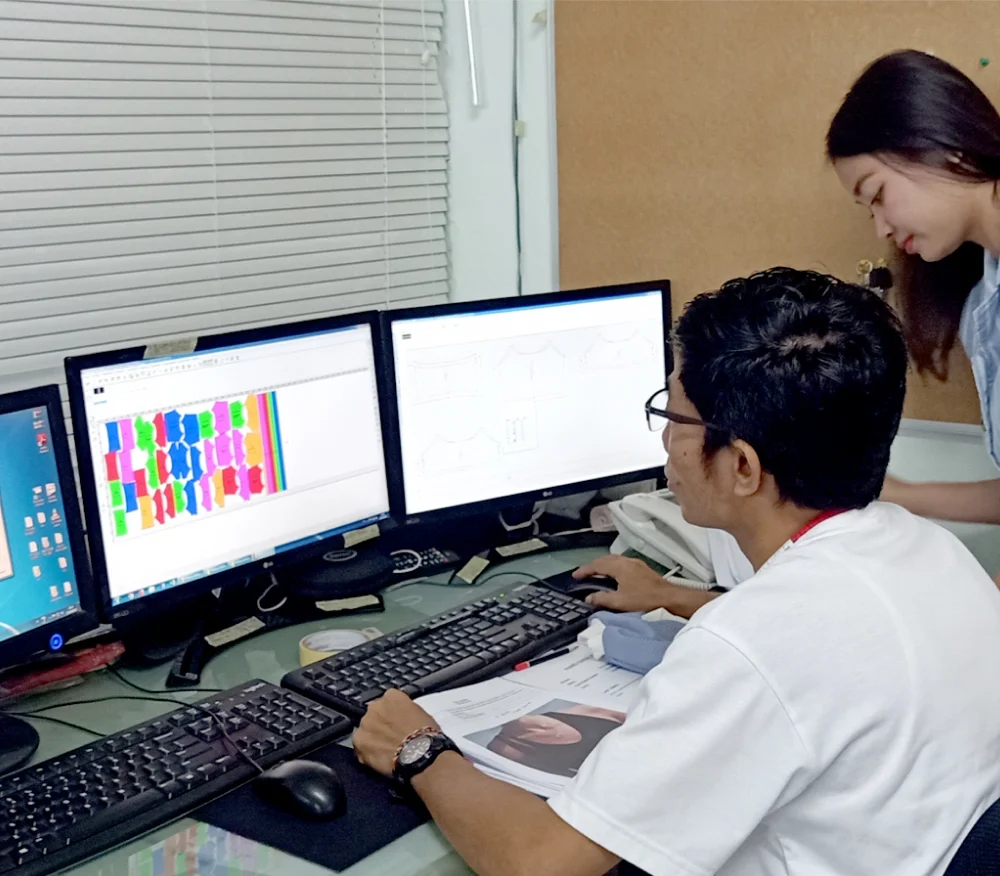

Designs can be shared as front and back screenshots, clear line drawings, or full tech packs. From there, we guide you through fabric selection using our stocked colours, or discuss importing specific fabrics if needed. Once the handover is confirmed, styles are prepared digitally using our 2D AutoCAD system before sampling begins.

This digital pattern stage is where sizing, proportions, and construction are finalised. Fit is resolved on screen before any fabric is cut, so by the time styles move into cutting and assembly, the foundation of the garment is already set.

The aim is to keep the process straightforward and transparent, so you know exactly how your designs move from handover to sampling and production.

Training

Every technician joining our team goes through structured in-house training led by senior staff. Training focuses on working with stretch fabrics, understanding the production flow and meeting quality expectations, ensuring consistency across every order.

Safety & SOP Culture

The facility operates under clear safety guidelines and established SOPs. While internal processes are not shared publicly, the goal is straightforward: a safe working environment, organised production and reliable results for every brand we support.

Quality Control

Before garments move to packing, they pass through multiple stages of quality control. Measurements, seams and finishing details are carefully checked so only approved pieces move forward. This process helps ensure consistency across sizes, colours and styles.

Packing

Finished garments are packed using biodegradable bags, with barcodes, brand tags and fabric hang tags added as required. Orders are organised clearly for export, keeping shipments clean, traceable and ready for dispatch.

facility Visits

We welcome facility visits by appointment for both start-up labels and established brands who would like to see how their products are assembled, meet the teams, and discuss their ideas and priorities first-hand. These visits provide a clear view of the sampling and production flow, and how each team works together across every stage of the process.